February 19, 2026

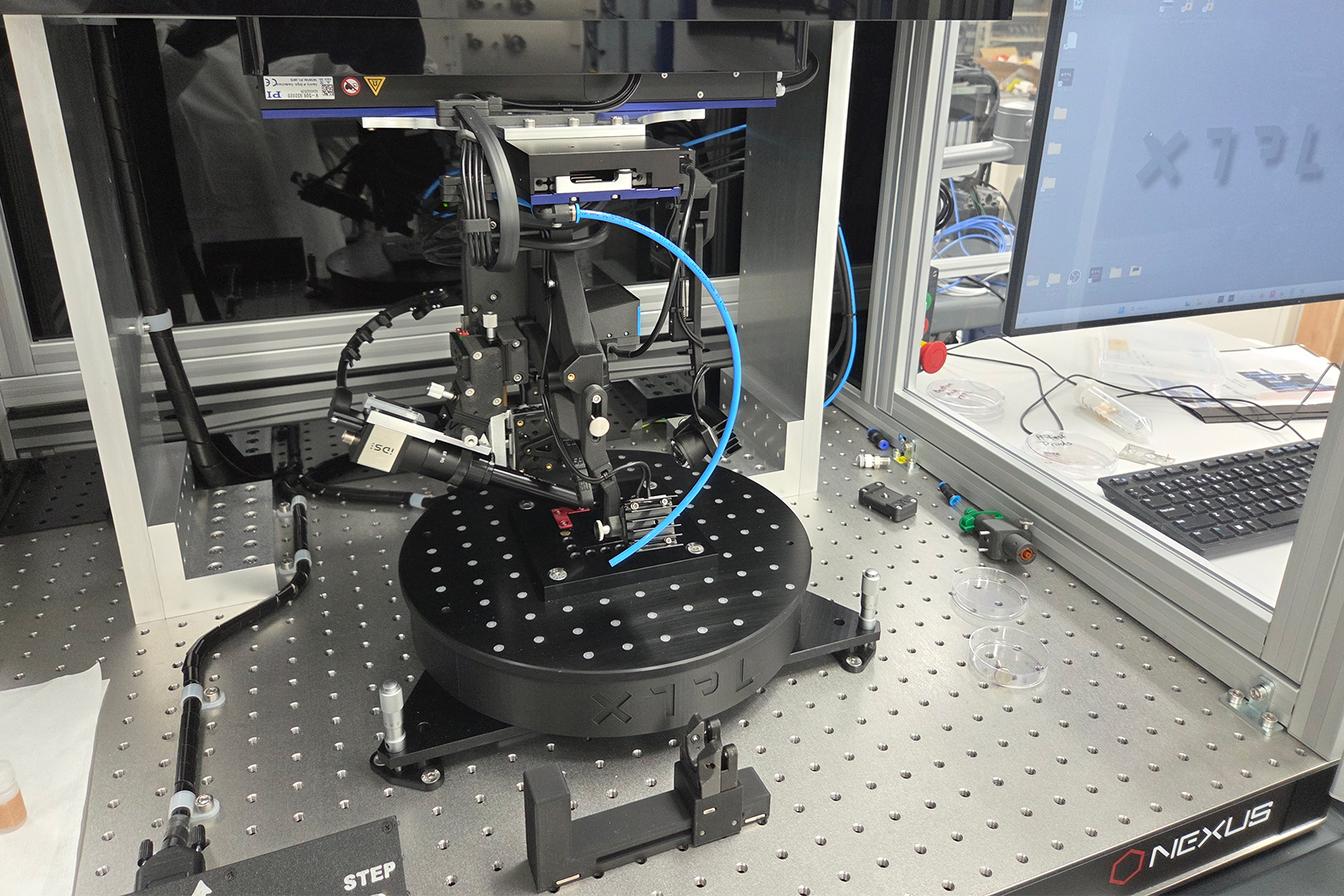

From flexible solar cells to novel energy storage systems, developing breakthrough clean energy technologies requires tools that are both precise and adaptable. The XTPL Delta Printing System, one of our most advanced fabrication tools at the Testbeds, is helping innovators do just that by prototyping faster, smarter, and at the microscale.

Revolutionary printing capabilities

The XTPL Delta system transforms clean energy device prototyping with three game-changing capabilities:

Ultra-high aspect ratio with high-resolution printing

The system prints with a line width of 1–5 µm and delivers exceptional aspect ratios (3:1 height to width) in printed features. This means taller, more conductive traces with better electrical performance—attributes that are essential for reducing resistive losses in solar cell interconnects, creating robust contacts for power electronics, and printing thick-film components that can handle higher current densities.

Printing on component sidewalls

Unlike conventional fabrication tools, the Delta can print directly on the vertical sidewalls and edge features of components. This unique capability enables innovative device architecture for embedded sensors, vertical interconnects in stacked energy storage systems, and conformal electronics for next-generation power modules.

Bond wire replacement through direct printing

The Delta system can print conductive interconnects directly onto components, potentially eliminating the need for traditional wire bonding in many applications. This opens new pathways for creating more compact, reliable, and cost-effective power electronics and energy conversion devices, from solar inverters to battery management systems.

Precision meets accessibility

What truly sets the XTPL Delta system apart, and why it’s become a go-to tool at the Testbeds, is its ease of use.

With tool-less cartridge and nozzle switching, users can go from setup to printing in minutes without the need for specialized cleanroom training. The system works with high-viscosity materials and can run for 12+ hours unattended, making it ideal for both short sprints and long experiments.

Joey Law, Testbeds staff scientist responsible for the Delta system, describes it best:

“It’s incredibly user-friendly. Researchers can walk in, quickly switch materials or substrates, and get right to work without jumping through hoops. The ability to print across a variety of surfaces, including on component sidewalls and stepped features with consistent resolution, really opens up new possibilities that simply weren’t available before.”

Lowering barriers to high-precision fabrication

While the Delta system is a powerful tool for hard tech innovation, the six-figure price tag can be prohibitive to early-stage teams. But at the Testbeds, users have open, pay-per-use access to this printer (and many other cutting-edge fabrication tools), making capital go further with zero intellectual property entanglement, unlike many other shared innovation facilities. Whether you’re from academia, a startup, or a corporate R&D group, our platform provides the infrastructure you need to test, iterate, and refine your technology at a pace that fits your technology development plans—and for a much more modest price than purchasing equipment or licensing fabrication services.

Explore the XTPL Delta Printing System at the Testbeds

If you’re developing the next big thing in clean energy, we invite you to take advantage of this powerful tool. Contact the Testbeds team to schedule time on the system and talk with our professional staff scientists about how the tool can support your prototyping needs.