Pouch Cell Prototyping

Opening in 2026, the new battery lab at the Washington Clean Energy Testbeds will provide pay-per-use open access to a world-class pilot-scale pouch cell production line. The new lab will enable innovators from both academia and industry to prototype batches of commercially relevant pouch cell batteries, with tools for every step from material processing to formation and testing. This lab will fill a critical gap between lab-scale research and commercial cell production, allowing for more rapid validation of new battery materials and cell architectures. Read the press release here.

The 1,600 ft2 space will include a dry room (-40°C dew point) with tools for electrode slurry mixing, material coating, and pouch cell assembly, as well as an ambient room with battery cyclers, a glove box, and other support equipment. View the floor plan here.

The standard-size pouch cell at the Testbeds is 89 mm wide x 125 mm long and up to 6 mm thick, with a cell capacity of up to approximately 10 amp-hours.

Inquire to start planning your project.

Dry Room

Primix 3D-2 Hivis Dispersion Mixer — up to 2 L capacity

Primix 3D-5 Hivis Dispersion Mixer — up to 5 L capacity

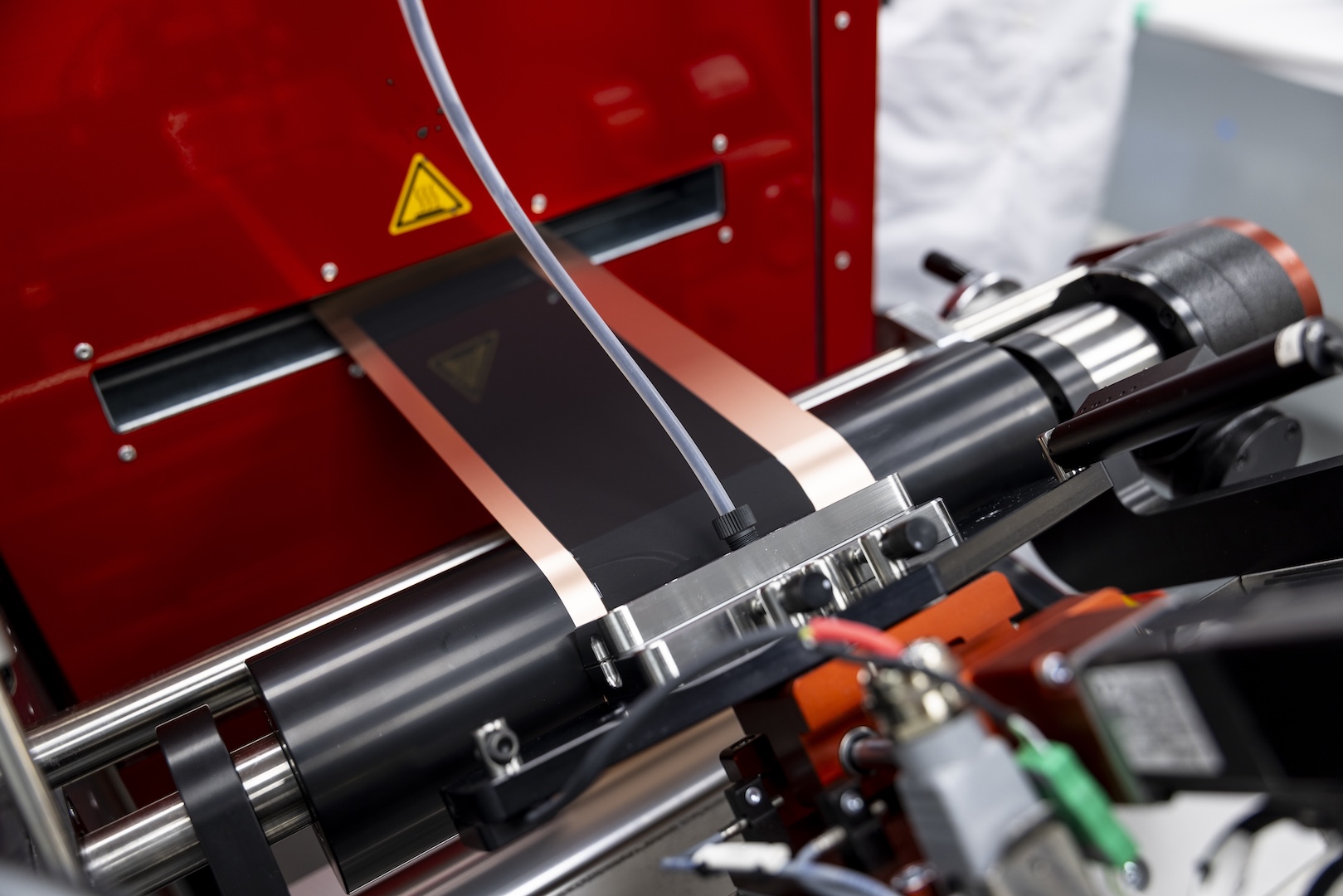

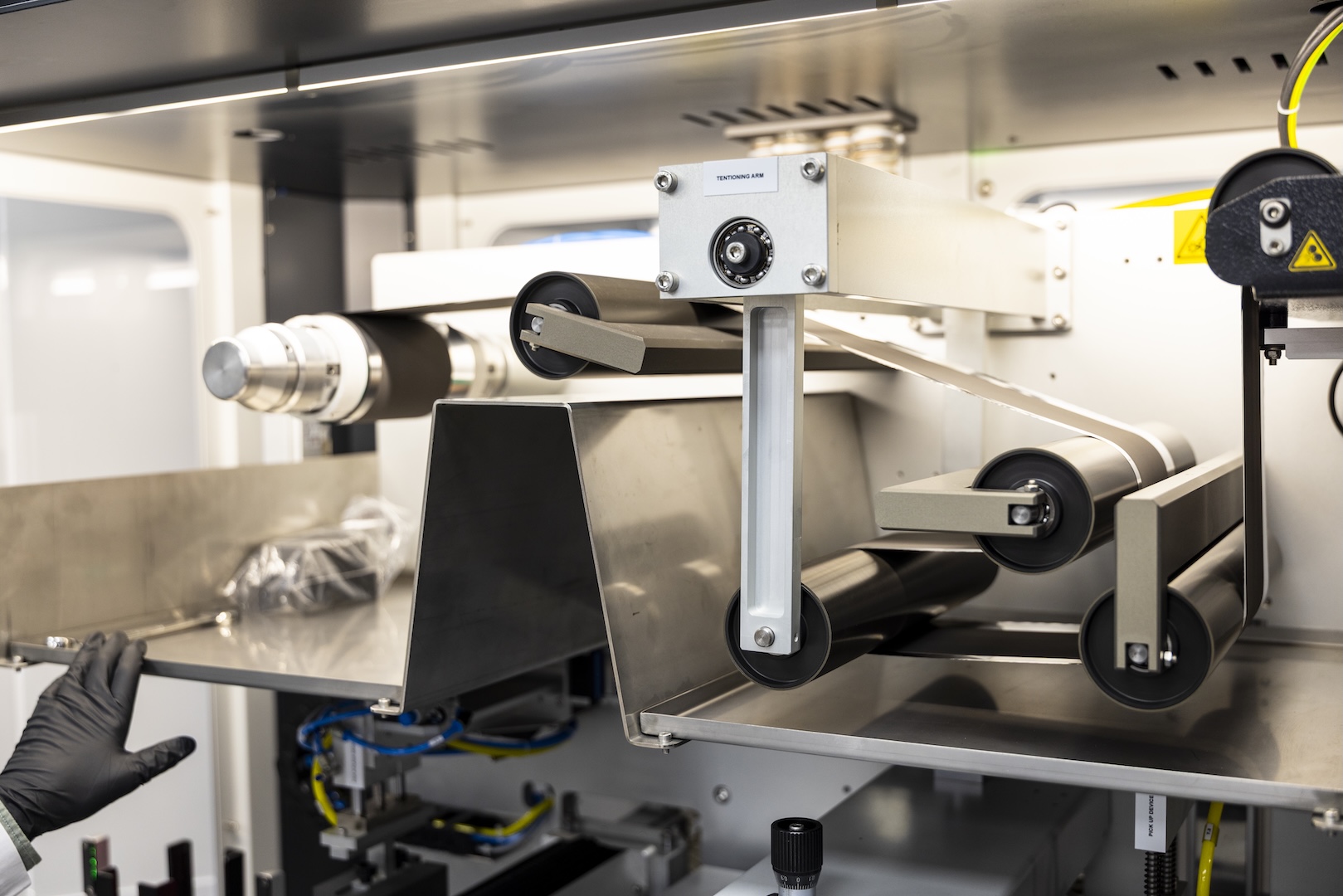

FOM Technologies Compact Modulo Slot-Die Coater

MTI Corporation Calendering Machine

Coming soon: FOM Technologies Calendering Machine

Electrode Cutting

Digatron Systems AUTOMATIC ELECTRODE CUTTING UNIT

Z-Fold Stacking

Digatron Systems AUTOMATIC CELL Z FOLD STACKING UNIT

Tab Welding

Digatron Systems SEMI-AUTOMATIC TAB ULTRASONIC WELDING UNIT

Pouch Forming

Digatron Systems AUTOMATIC POUCH BLISTER FORMING UNIT

Cell Filling & Degassing

Digatron Systems AUTOMATIC CELL FILLING AND DEGASSING UNIT

Pouch Sealing

Digatron Systems AUTOMATIC POUCH CELL SEALING UNIT

Ambient Room

Maccor and Arbin 5V/5A Cyclers

Additional cyclers up to 60A per channel available in our battery testing lab

MBraun Labstar Pro Argon Glove Box

Battery Materials Development, Device Testing, and System Integration

In the same facility, the Testbeds have a wide range of state-of-the-art tools suitable for developing new battery materials and manufacturing processes. The Testbeds also house a full suite of materials characterization tools and battery cell testers. Together, the Testbeds facilities support innovation across scales, from coin cells and battery materials R&D to pilot batches of pouch cell prototypes.

Support for Battery Innovators

The Testbeds’ expert staff will provide battery fabrication guidance to support users regardless of where they are in the battery technology development pathway. From engineering advice to sourcing standard battery materials, the Testbeds’ battery lab will be fully equipped for rapid battery innovation.

Hands-On Training

The new UW Graduate Certificate in Battery Engineering, Materials and Manufacturing includes 9 months of remote learning courses and a 2-week intensive hands-on training experience in the new battery lab at the Washington Clean Energy Testbeds.

The Washington Clean Energy Testbeds have engaged technical colleges throughout Washington to support clean energy workforce development. The Testbeds will partner with Big Bend Community College — located in Moses Lake, WA and serving the broader Columbia Basin, including all of Grant and Adams counties and a portion of Lincoln County — to offer hands-on battery workshops in the new lab. A recent Washington State Department of Commerce grant to the Testbeds, FOM Technologies, and Argonne National Lab will support opportunities for students to train with tools and techniques used in battery plants like those under construction in the Columbia Basin.